Industrial Diamond Solutions

Leading manufacturer of high-quality industrial diamond tools, PCD, PDC, and carbide products. Delivering precision and performance for your cutting-edge applications.

Featured Products

Discover our range of high-quality industrial diamond tools and equipment.

PCD/PDC Tools

High-performance Polycrystalline Diamond tools for precision cutting and drilling.

Diamond Products

Premium quality natural and synthetic diamonds for industrial applications.

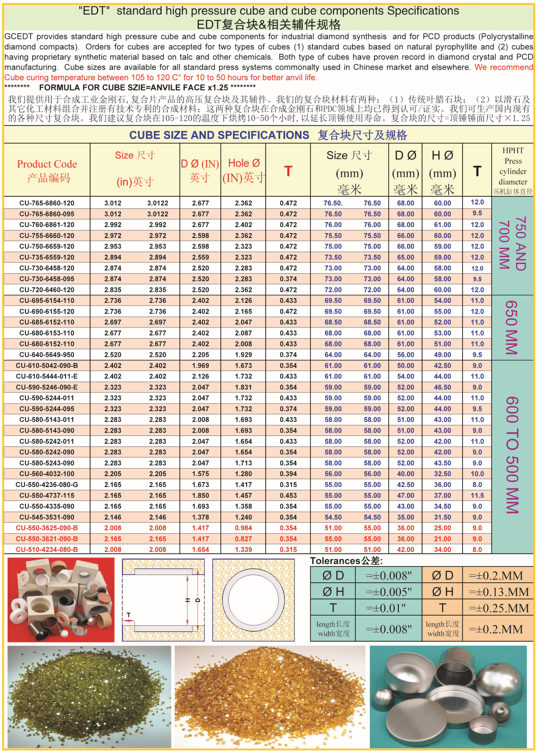

HPHT Products

Specialized products for High Pressure High Temperature applications.