Running a

successful business

since 1975

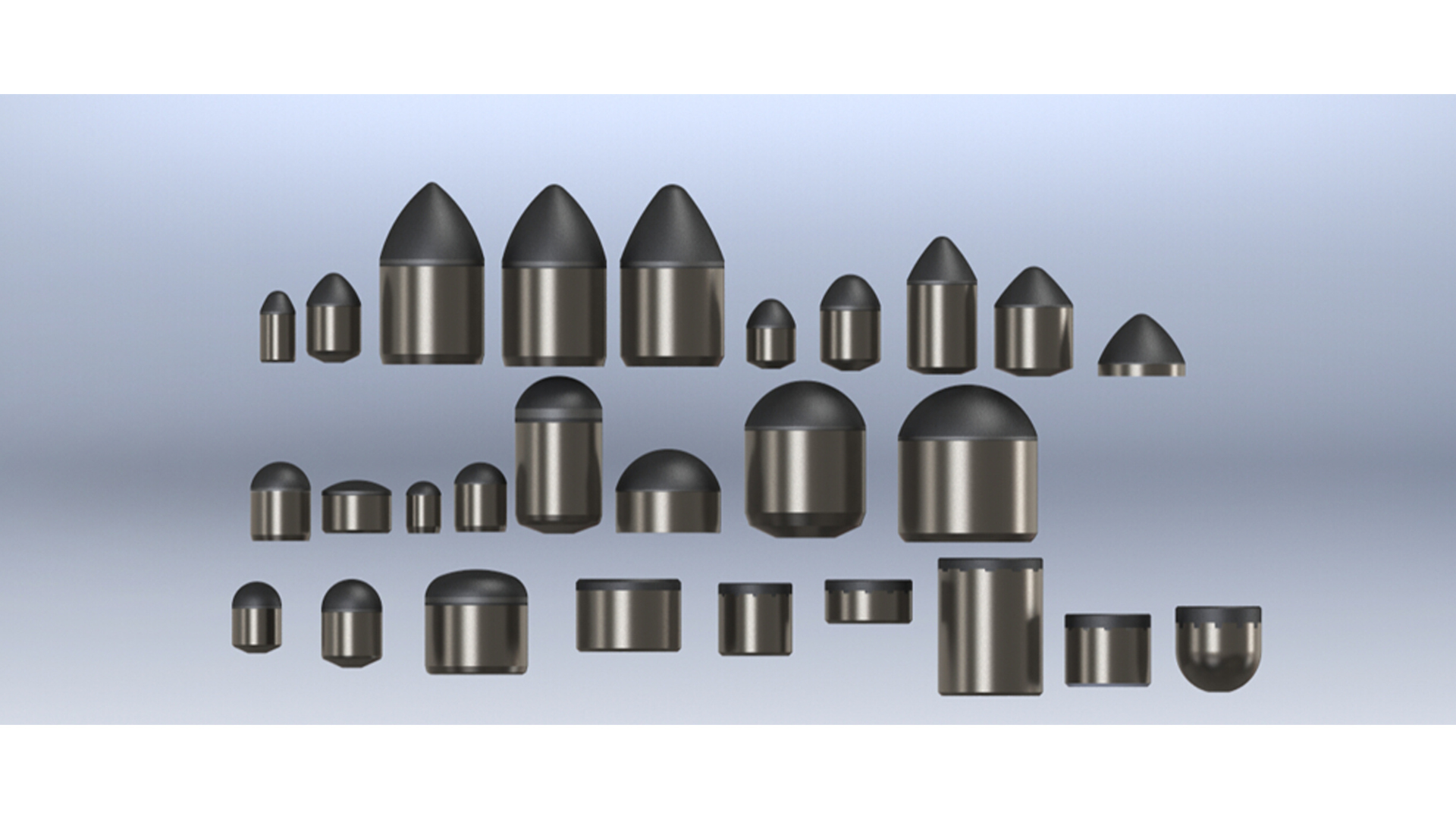

Guilin Color Engineered Diamond Technology (GCEDT) located in Guilin, Guangxi province, China produces premier quality long-lasting polycrystalline diamond (PCD) inserts for applications in down-hole drilling tools. GCEDT inserts have performed exceptionally well in harder to drill formations all over North American region. GCEDT designs, engineers, presses, and finishes its own polycrystalline diamond (PCD) products to exact customer specifications to ensure confidence that their high-performance product will perform under demanding down hole conditions.

PCD product family includes round top dome inserts for Hammer bits and Tricone Bits, flat cutters for PDC drag bits using proprietary transition layer technology to optimize impact resistance as well as thicker and harder diamond layers that improves the abrasion resistance of the PCD layer. GCEDT prides itself on an uncompromising commitment to outstanding quality, superior customer service, and continuous improvement through our engineering teams to meet high performance demands of our customers in most demanding oil exploration and development projects.

Shri Navin B Parsana entered the

Diamond Business individually in Bombay from 1975. He started a Diamonds

manufacturing unit in Bombay and also traded in Diamonds. In 1980, he started a firm

named "PINK STAR" for setting up a traditional unit for cutting and polishing of

diamonds.

Subsequently Mr. Navin B. Parsana went to Belgium and obtained a diploma as a

"DIAMOND CUTTER" in Antwerp in the field of semi automatic method of Diamond Cutting

and Polishing.

In onder to achieve the objective of starting a semi automatic method of cutting and

polishing unit, another partnership firm was established in the name and style of

"THE DIAMOND CORPORATION" during 1984. The said firm then installed semi automatic

polishing mills for manufacturing of diamonds at Virwani Industrial Estate, Goregion

(E), Mumbai-400063. The entire production of polished diamonds was manufactured with

the then new technology of semi automatic cutting and polishing concept by using

sophisticated high tech tools like double head bruiting machines, sawing machines,

Laser machine, semi automatic dops and tungs, press pots ete and exported ta various

countries.

Another firm by the name "The Laser Diamond Corporation" was formed and the first

Laser machine to cut (Cleave) rough diamonts was imported from USA to India in 1985

Also the group of companies became agents of various semi automatic diamond cutting

& polishing machinery suppliers from Belgium. Another private limited firm by the

name Heaven Diamonds Pvt. Ltd., was started during 1985. Additional Semi Automatic

Polishing Benches were installed to cater to the demand for the export market. Along

with the new semi automatic polishing benches and other type of new machinery, one

sophisticated CNC Lathe from MAZAK Company Japan was also imported to increase the

accuracy and production.

Indian manufacturing were facing stiff competition with the traditional method in

the early 80' to match the International standard of cutting and polishing (Quality

& Quantity) In 3 years the company the Indian Diamond Cutting & Polishing Industry

from the traditional method to the Semi Automaric method for which the Indian

Govemment gave "The Rajiv Gandhi Award" Lo Navin B Parsana. An award which is given

by the Indian Goverment for special achievement. The company developed experlise

over the years in the line of cutting & polishing of Rough Diamonds which are

comparable with the Cut & Polished Diamond of Belgium & Israel in the International

market.

Australian Rough Diamonds from the Argyle Mines of Australia started coming to India

and Belgium for trading & manufacturing. These Australian rough diamonds were very

hard to polish, so in 1989 the company started producing the Diamond Impregnated

Scaife. And PCD to brut diamand. Heaven Diamonds Pvt.Ltd. was the first company in

India to invent The Diamond Impregnated COBALT FREE scaife. With the belp of this

invention the Australian hard Rough Diamonad could be cut & polished 20 times

faster.

With the help of the Semi Automatic method rough sawn diamonds could be cut &

polished faster with precision and maximum yield. The Bruting (Shaping) of the sawn

rough diamonds was done with the help of low quality Boart Diamonds. The company

then started manufacturing the PCD in 1989 and started using them to recondition

scaife, OPEN SCAIFE FOR POLISHING and brut (shape) rough sawn diamonds.

Subsequently our company became one of the biggest manufacturers of Diamond scaife

in Indin and then slowly other Indian companies also started manufacturing then. Now

in order to maintain a consistent production of good quality Diamond Scaife some of

the raw ranterials like Metal powder, suitable cobalt & tungsten powder, etc. needed

to be imported regularly, but due to bigh import custom duties, custom harassments

and inconsistent supply farm the foreign suppliers, we decided to start manufacturng

them in India so from 1998 we started manufacturing Cobalt, Carbide and Carbide

substrate for manufacturing PDC/PDC, Tungsten powder, and PCD in Daman & AVIS

MACHINE PVT.LTD. AtSurat (Gujrat) India.

Since 1985 the group of companies provided services as under :-

- Set up a cutting & polishing factory on turn key basis since 1985.

- Set up a factory to manufacturing diamond Impregnatedscaif to polished diamond and PCD/PDC since 1987

- Set up a factory to manufacture PCD since 1989, as we know the behavior of natural and synthetic diamonds because we are in the diamond trade since 1975.

We provided consultancy as under :-

- To select the press and matrix.

- To select the diamond powder suitable for PCD/PDC applications.

- To select the treatment for powder.

- To select the carbide Substrate.

- To select the suitable cleaning/anaeling process for carbide.

- To select the Anvil.

- Provide cube manufacturing process.

- To select the HPHT process.

- To provide lapping process.

- To provide the grinding process.

- To provide the testing method.

- To select various type of manufacturingfor diamond assortment, cutting & polishing, laser machine, planning machine,etc to set up a diamond cutting & polishing factory.