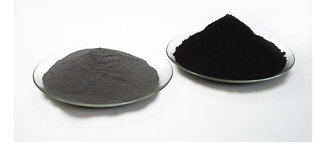

Tungsten Carbide Powder(WC)

Physical Properties

| Av. Particle Size | 2.0 - 4.0 | 5.0 - 7.0 | 7.0 - 9.0 | 10.0 - 15.0 |

| F.S.S.S(Mm) Apparent density g/cc. |

2.5 - 3.0 | 3.0 - 4.0 | 3.5 - 4.0 | 4.0 - 6.0 |

| Chemical Composition | ||||

|---|---|---|---|---|

| Total Carbon as CTOT% | 6.12 6.16 | 6.12 6.16 | 6.12 6.15 | 6.12 6.13 |

| Free Carbon as CFREE% | 0.04 Max. | 0.05 Max. | 0.05 Max. | 0.07 Max. |

| Bonded Carbon by diff.,% | 6.08 Min. | 6.08 Min. | 6.07 Min. | 6.06 Min. |

| Oxygen as O2% | 0.04 Max. | 0.04 Max. | 0.04 Max. | 0.04 Max. |

| Iron as Fe% | 0.05 Max. | 0.05 Max. | 0.05 Max. | 0.05 Max. |

| Molybdenum as Mo,% | 0.03 Max. | 0.03 Max. | 0.03 Max. | 0.03 Max. |

| Silicon as Si,% | 0.003 Max. | 0.003 Max. | 0.003 Max. | 0.003 Max. |

| Sodium as Na,% | 0.002 Max. | 0.002 Max. | 0.002 Max. | 0.002 Max. |

| Potassium as K,% | 0.001 Max. | 0.001 Max. | 0.001 Max. | 0.001 Max. |

| Calcium as Ca,% | 0.002 - Max. | 0.002 - Max. | 0.002 - Max. | 0.002 - Max. |

Other grains sizes and mixed carbide - cobalt are available upon request.

Principal Application

Tungsten carbide powders are used to manufacturevarious graded powder for cemented. Tungsten carbide products and manufacture of diamond segments to increase the hardness and abrasion resistance of the tools.

Packing

1 kg and 5 kg packing in polythene bags.

REDUCED IRON METAL POWDER

Apparent Density : 2.4 - 2.5 g/cm3

Chemical Purity : 99.8 %

Hydrogen Loss : 0.8 %

Particle Size : 2-4 micron

Typical Application : Manufacturingof Diamond tools, ferrite cores, Sintered machine parts.

COBALT OXIDE POWDER

Assay (As Co) : 72.5 % Min

Fe : 100 ppm max.

Mg : 100 ppm max.

Ni : 150 ppm max.

Na : 050 ppm max.

Zn : 003 ppm max.

Particle Size : -300 Mesh

Typical application : Used in Manufacturing ceramics, glass, enamals, catalyst, inks, rubber, oil, greases, cosmetics food additives etc.