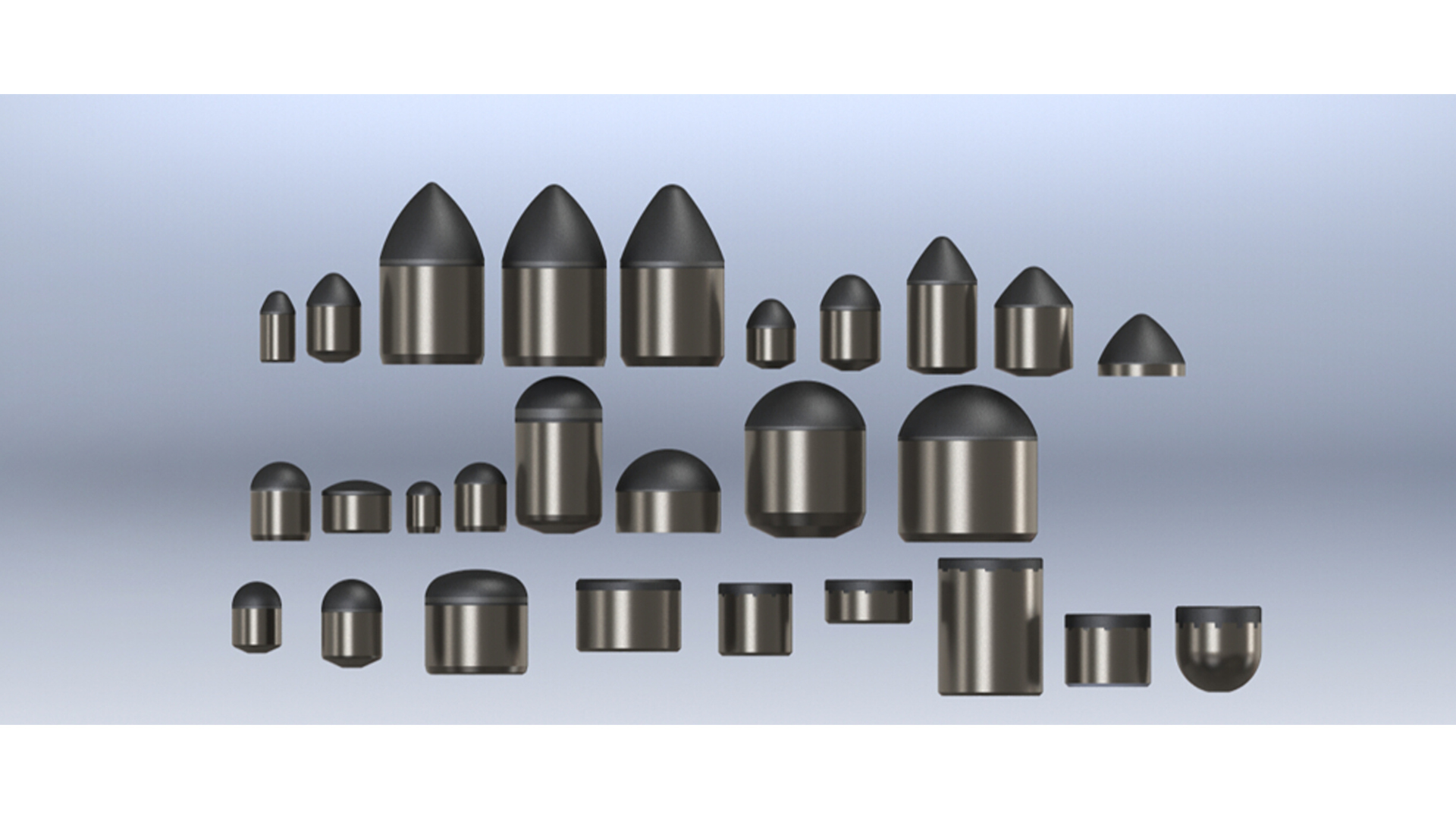

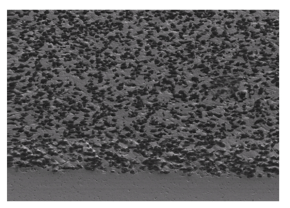

EDT-Diamond dome insert are two layered engineered products designed for high impact resistant applications such as encountered in percussive drilling for oil and gas. Two layered structures have also found application in three cone rock bits. They are available in sizes suitable for both types of bits.

All our long product is one piece (SINGLE PIECE WITHOUT BRAZING). Our 3/4 inch and i inch dome insert have found sucessful application in geographical locations rangign from West and Esat Texas, New Mexico, Oklahoma, Arkansas ,WV and NEUS regions.

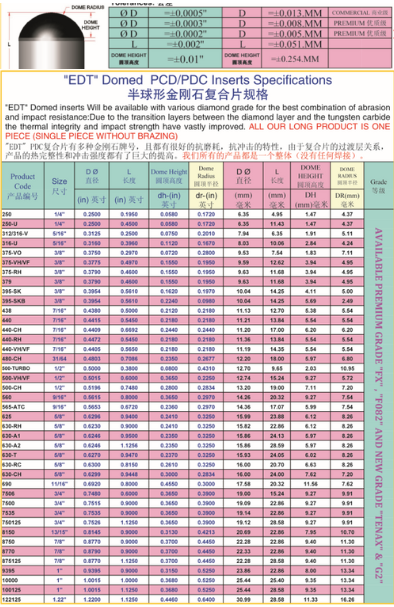

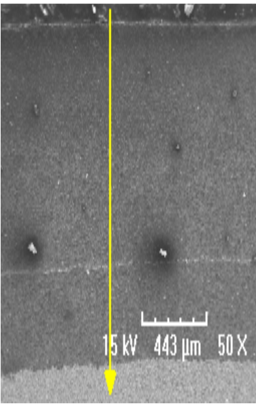

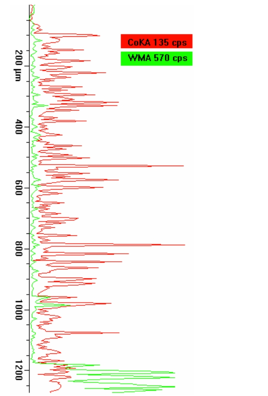

- The working layer Intergrity

- The bonding between the working layer and the trabsition layer.

- The interface integrity between transition layer carbide substrate. As can be seen in the following micrographs, the layers are homogenous and well bonded.

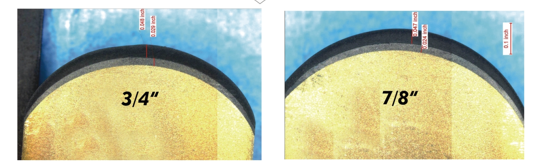

Insert are evaluated for their metallurgical features by microscopic examination of the section following micrographs show :

EDT-Diamond Hammer bit inserts are characterized by highest thickness of first layer than found in any competitive product in the market place. Typical thickness for the first layer is in excess of 0.045 inch and transition layer of 0.030 inch.

Photograph shows half cut view of both 3/4 inch insert(left) and 7/8 inch insert (right). Transition layerand first layer can be seen with layer thicknesses marked.

EDM section of both 3/4 inch and 7/8 inch insert.

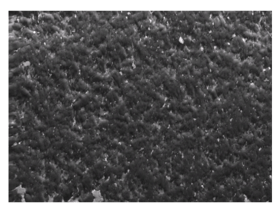

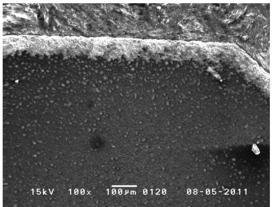

Scanning electron micrograph of outer working layer. The layer is more than 9o% by volume diamond followed by a specially engineered transition layer that intimately bonds with the carbide substrate as shown below.

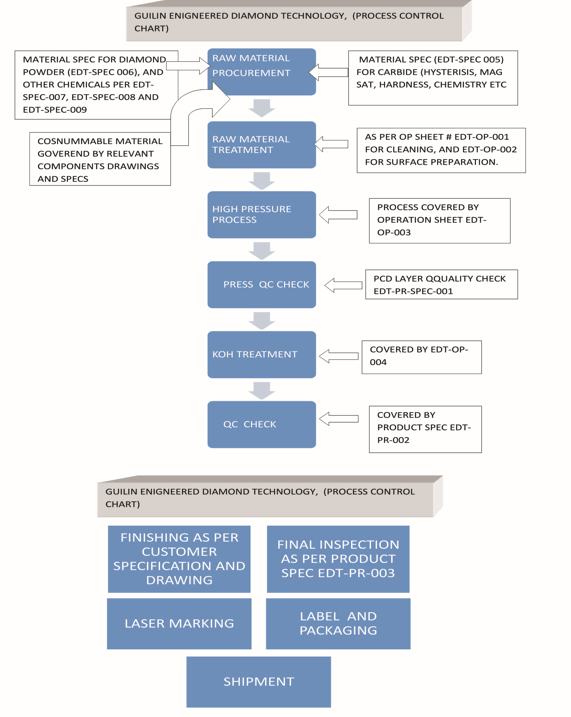

Inserts are manufactured under strict guideline where all high pressure and high temperature components, raw materials for inserts are regulated. All batches of inserts are checked for the following:

- Dye penetration to check presence of cracks

- Thermal stability test

- Drop Weight test

- Impact Fatigue where inserts are subjected to impact at a rate of 20 hits per minute using a 5 ton machine.

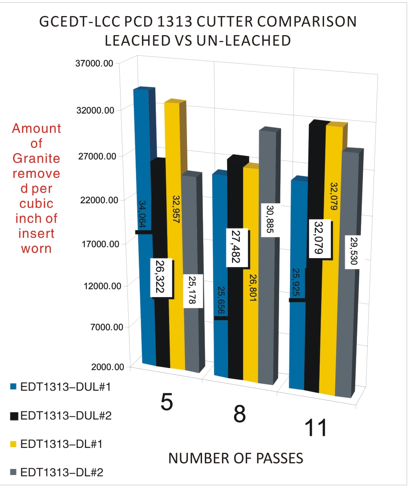

HPHT has developed a new family of cutters called LCC(Low Catalyst Cutter) cutters characterizedby low volume percent of non diamond phase in the structure. LCC cutters are not affected by the leaching process and perform exceptionally well against commercially available leached cutters. Leached cutters have voids in their structure and are prone to cracking.

- All pcd cutters contain varying amount of binder also called catalystic Material.

- Properties of PCD is determined by the amount and type of binder in the structure.

- As temperature of PCD increase during drilling, binder expands more than diamond causing diamond to diamond bond.

- Partial leaching (shallow or deep) employed to reduce the amount of binder phase, However it creates voids in the structure

Cobalt and tungsten amount is reduced However, Acid can penetrate beyond 50 to 60 micron depth from the surface since binder phase is not contiguous.

- Specific gravity of PCD layer can be used to determine the amount of binder content of the PCD layer.

- When the amount of binder in the PCD structure is small , the performance of cutter is the same as leached product.

- PCD cutters with small amount of binder show insiginidicant depth of leaching (Less than 40 micron) even after subjected to long exposure to leaching either by electrolystic or acid leaching process.

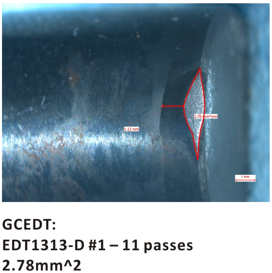

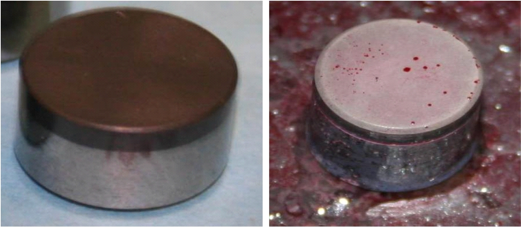

Photograph show features of A-US Cutter-1313 before and after thermal cycling(14 cycles).

All commercially available PCD cutters have varying weight percentage of non diamond phase in their structure. The non diamond phases have different properties compared to the diamond phase in terms of thermal conductivity, thermal expansion and elastic modulus. Upon heating and cooling non diamond phase tend to cause development of porosity or cracking due to their higher coefficient of thermal expansion. Thermal cycling test is a useful test that is commonly used to determine quality of PCD products. In Diamond thermal test, cutters are exposed to 750°C in air for duration of time and then rapidly cooled to room temperature. They are then inspected for any cracks and porosity and then put in to the furnace for further cycling.

Photograph show features of D-US Cutter-1308 before and after thermal cycling(14 cycles). Developement of porosity or presence of sub surface cracksis indicated by oozing of dye after application of developer.

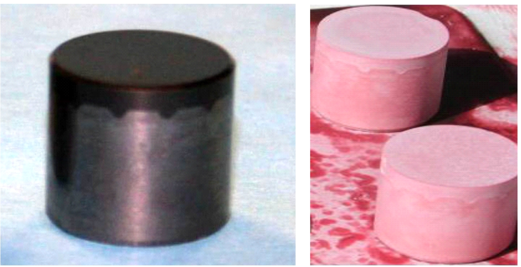

Photograph show features of HPHT before and after thermal cycling(14 cycles).There is no sign of porosity or sub surface cracks.