Cobalt Powder

Principal Application

Diamond tools, cemented carbide tools, hard metals, glass industries, diamond polishing scaives.

Packing

1 kg packing available in cardboard box with inner LDPE

bags sealed in inert atmosphere.

25 kg & 50 kg packing in metal drum with inner LDPE bags sealed in inert atmosphere.

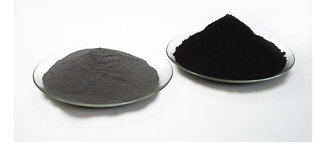

EXTRA FINE COBALT POWDER

Fisher grain size 1.1 to 1.5 micron.

| Chemical Analysis | ||

|---|---|---|

| Co | 99.8% | Min. |

| Fe | 0.05% | Max. |

| Mn | 0.001% | Max. |

| Zn | 0.003% | Max. |

| Na | 0.03% | Max. |

| O2 | 0.6% | Max. |

ULTRA FINE COBALT POWDER

Fisher grain size 0.9 to 1.1 micron.

| Chemical Analysis | ||

|---|---|---|

| Co | 99.8% | Min. |

| Fe | 0.05% | Max. |

| Mn | 0.001% | Max. |

| Zn | 0.003% | Max. |

| Na | 0.03% | Max. |

| O2 | 0.8% | Max. |

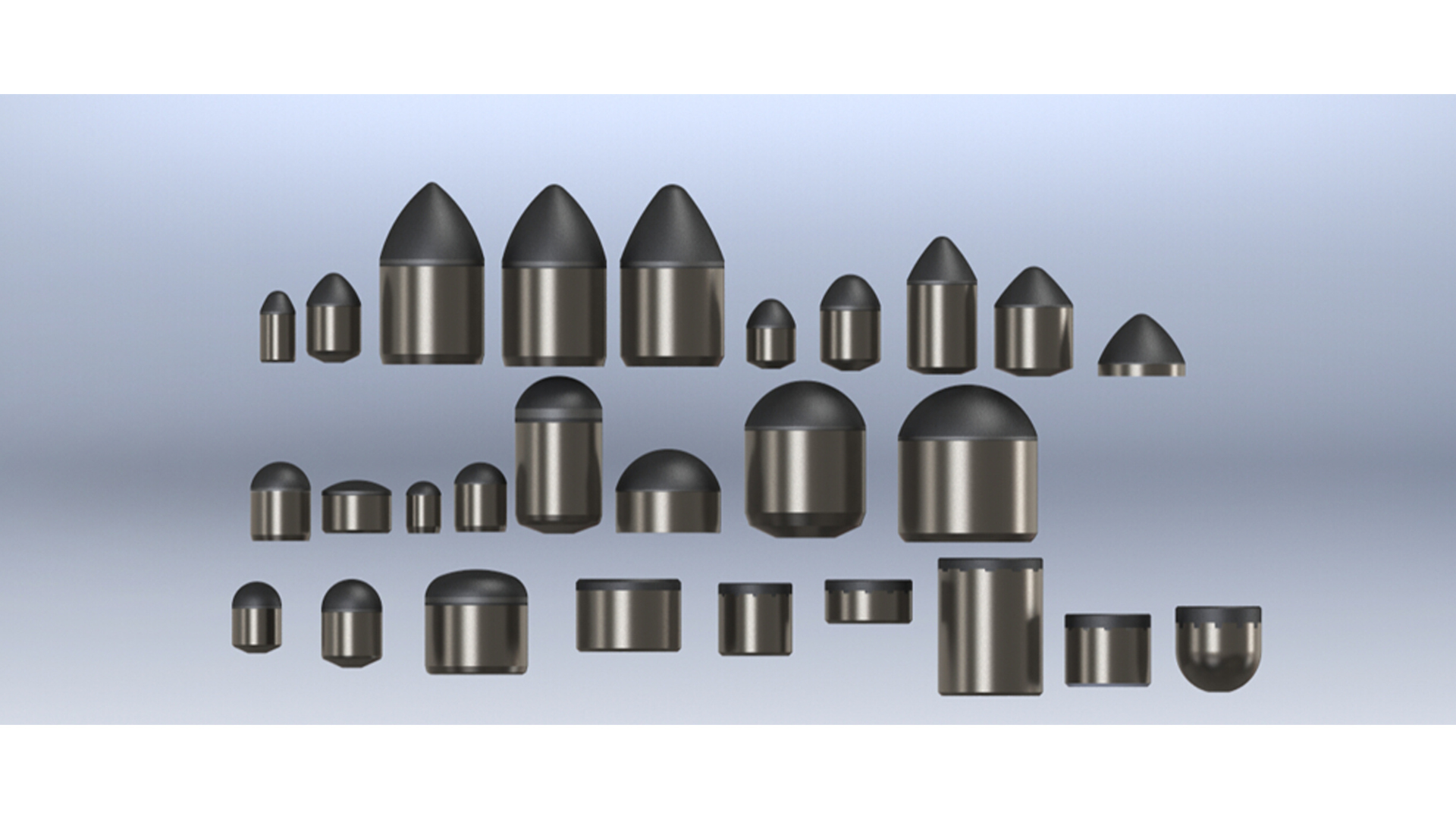

Application

- Buttons for DTH bits.

- Drill steel inserts (DSI) for drill rods.

- Wire drawing nibs.

- Bar and tube drawing pellets.

- Wear parts, specialtips, blanks etc., as per requirement / drawing.

- Cold heading pellets.

Also, we produce tungsten metal and tungsten carbide powders, It is availablein different particl sizes.

REDUCED IRON METAL POWDER

Apparent Density : 2.4 - 2.5 g/cm3

Chemical Purity : 99.8 %

Hydrogen Loss : 0.8 %

Particle Size : 2-4 micron

Typical Application : Manufacturingof Diamond tools, ferrite cores, Sintered machine parts.

COBALT OXIDE POWDER

Assay (As Co) : 72.5 % Min

Fe : 100 ppm max.

Mg : 100 ppm max.

Ni : 150 ppm max.

Na : 050 ppm max.

Zn : 003 ppm max.

Particle Size : -300 Mesh

Typical application : Used in Manufacturing ceramics, glass, enamals, catalyst, inks, rubber, oil, greases, cosmetics food additives etc.

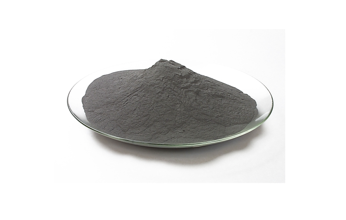

Tungsten Carbide Powder(WC)

Physical Properties

| Av. Particle Size | 2.0 - 4.0 | 5.0 - 7.0 | 7.0 - 9.0 | 10.0 - 15.0 |

| F.S.S.S(Mm) Apparent density g/cc. |

2.5 - 3.0 | 3.0 - 4.0 | 3.5 - 4.0 | 4.0 - 6.0 |

| Chemical Composition | ||||

|---|---|---|---|---|

| Total Carbon as CTOT% | 6.12 6.16 | 6.12 6.16 | 6.12 6.15 | 6.12 6.13 |

| Free Carbon as CFREE% | 0.04 Max. | 0.05 Max. | 0.05 Max. | 0.07 Max. |

| Bonded Carbon by diff.,% | 6.08 Min. | 6.08 Min. | 6.07 Min. | 6.06 Min. |

| Oxygen as O2% | 0.04 Max. | 0.04 Max. | 0.04 Max. | 0.04 Max. |

| Iron as Fe% | 0.05 Max. | 0.05 Max. | 0.05 Max. | 0.05 Max. |

| Molybdenum as Mo,% | 0.03 Max. | 0.03 Max. | 0.03 Max. | 0.03 Max. |

| Silicon as Si,% | 0.003 Max. | 0.003 Max. | 0.003 Max. | 0.003 Max. |

| Sodium as Na,% | 0.002 Max. | 0.002 Max. | 0.002 Max. | 0.002 Max. |

| Potassium as K,% | 0.001 Max. | 0.001 Max. | 0.001 Max. | 0.001 Max. |

| Calcium as Ca,% | 0.002 - Max. | 0.002 - Max. | 0.002 - Max. | 0.002 - Max. |

Other grains sizes and mixed carbide - cobalt are available upon request.

Principal Application

Tungsten carbide powders are used to manufacturevarious graded powder for cemented. Tungsten carbide products and manufacture of diamond segments to increase the hardness and abrasion resistance of the tools.

Packing

1 kg and 5 kg packing in polythene bags.

Tungsten Metal Powder(W)

Physical Properties

| Av. Particle Size | 1.5 - 3.0 | 4.0 - 6.0 | 6.0 - 9.0 | 9.0 - 15.0 |

| F.S.S.S(Mm) Apparent density g/cc. |

2.2 - 3.0 | 3.0 - 4.0 | 3.8 - 5.8 | 4.0 - 6.0 |

| Chemical Composition | ||||

|---|---|---|---|---|

| Tungsten (excluded2O) as W, % |

99.8 Min. | 99.8 Min. | 99.8 Min. | 99.8 Min. |

| Oxygen content as 2O,% | 0.40 Max. | 0.30 Max. | 0.30 Max. | 0.25 Max. |

| Iron as Fe,% | 0.05 Max. | 0.05 Max. | 0.05 Max. | 0.05 Max. |

| Molybdenum as Mo,% | 0.03 Max. | 0.03 Max. | 0.03 Max. | 0.03 Max. |

| Silicon as Si,% | 0.003 Max. | 0.003 Max. | 0.003 Max. | 0.003 Max. |

| Sodium as Na,% | 0.003 Max. | 0.003 Max. | 0.003 Max. | 0.003 Max. |

| Potassium as K,% | 0.001 Max. | 0.001 Max. | 0.001 Max. | 0.001 Max. |

| Calcium as Ca,% | 0.002 Max. | 0.002 Max. | 0.002 Max. | 0.002 Max. |

Other grains sizes are available upon request.

Principal Application

These powder are mostly used in the manufacture of diamond segments by hot pressing as additives in the metal matrix to improve the diamond reteation and cutting ability. Also these powder are used to manufacture electrical contact and tungsten carbide powders.

Packing

1 kg and 5 kg packing in polythene bags.

Fused Tungsten Carbide Powders(FTC)

Chemical Composition

| Tungsten as W, % | 95.0 - 97.0 | 95.0 - 97.0 |

| Total carbon as C TOT, % | 2.5 - 3.5 | 2.5 - 3.5 |

| Free carbon as C FREE, % | 0.1 Max. | 0.1 Max. |

| Iron as Fe, % | 0.4 Max. | 0.4 Max. |

| Cobalt as Co, % | - | 0.2 - 0.4 |

- Mesh size as per ASTM/MBSS standard, -20 to +600 as per requirement of the customer.

- Sieve Analysis can be provided as per the required size on request.

Principal Applications

These powders have very high hardness and outstanding abrasion

resistance. These are used to manufacture diamond tools for cutting of very abrasive

materials.

F.T.C is also useful to :

- Manufacture self lubricating sintered bearing.

- Manufacture contact material of current flow performance in arc resistance, adhesion resistance & contact resistance.

- Manufacture brushes application in electric motors & generators.

- Friction material for brakes.

Packing

1 kg and 5 kg packing in polythene bags.